HEAT TREATMENT

HEAT TREATMENT

CAPABILITIES

…………………………………

…………………………………

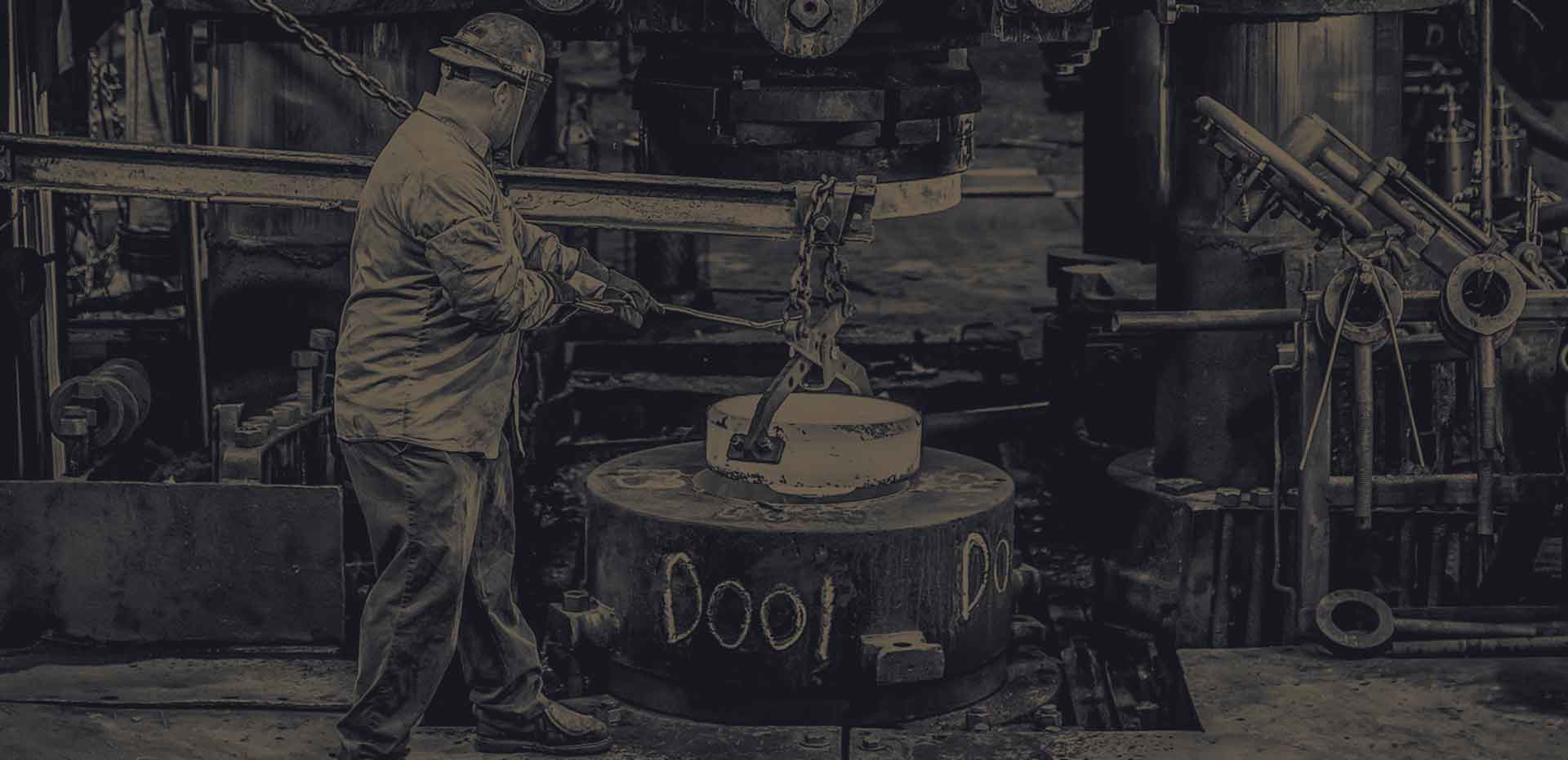

The primary reasons steel is such an important material is due to the tremendous flexibility of attainable mechanical properties, which are established in the heat treat process. The functional benefits of steel are born in heat treat and McConway & Torley recognizes the importance of a high quality, well controlled heat treat process.

M&T heat treat operators utilize 10 gas fired recirculating furnaces that can hold temperatures within 0.5% of target. In addition to the furnaces, quench tanks, with circulating cooling and high-flow agitation, provide the rapid cooling necessary to achieve the most refined micro-structure. Operators utilize the furnaces and quench tanks to anneal, normalize, harden and temper high quality steel castings, which are then all qualified with our in-house mechanical property testing lab. M&T continues to invest in the heat treating operation to allow for high production throughput and repeatable mechanical properties.

Capacities and capabilities include:

- (10) Furnaces with interior cavities of at least 10’H x 12’Wx 12’D.

- Temperature control of +/- 10°F at 2000°F

- Load capacity of 15 Tons

- (2) 10,000 Gallon quench tank with high pressure agitation

- Dedicated quench tank heat exchanger/cooling tower & circulation for rapid heat removal.

- In-house mechanical testing, including tensile, hardness, ductility, and fatigue.

DROP US A LINE

…………………………………………… ……………………………………………

QUALITY RAIL PARTS AND EQUIPMENT

MARKET-LEADING EXPERTISE, PRODUCT, AND SUPPORT.