DEFENSE & ENERGY

DEFENSE & ENERGY

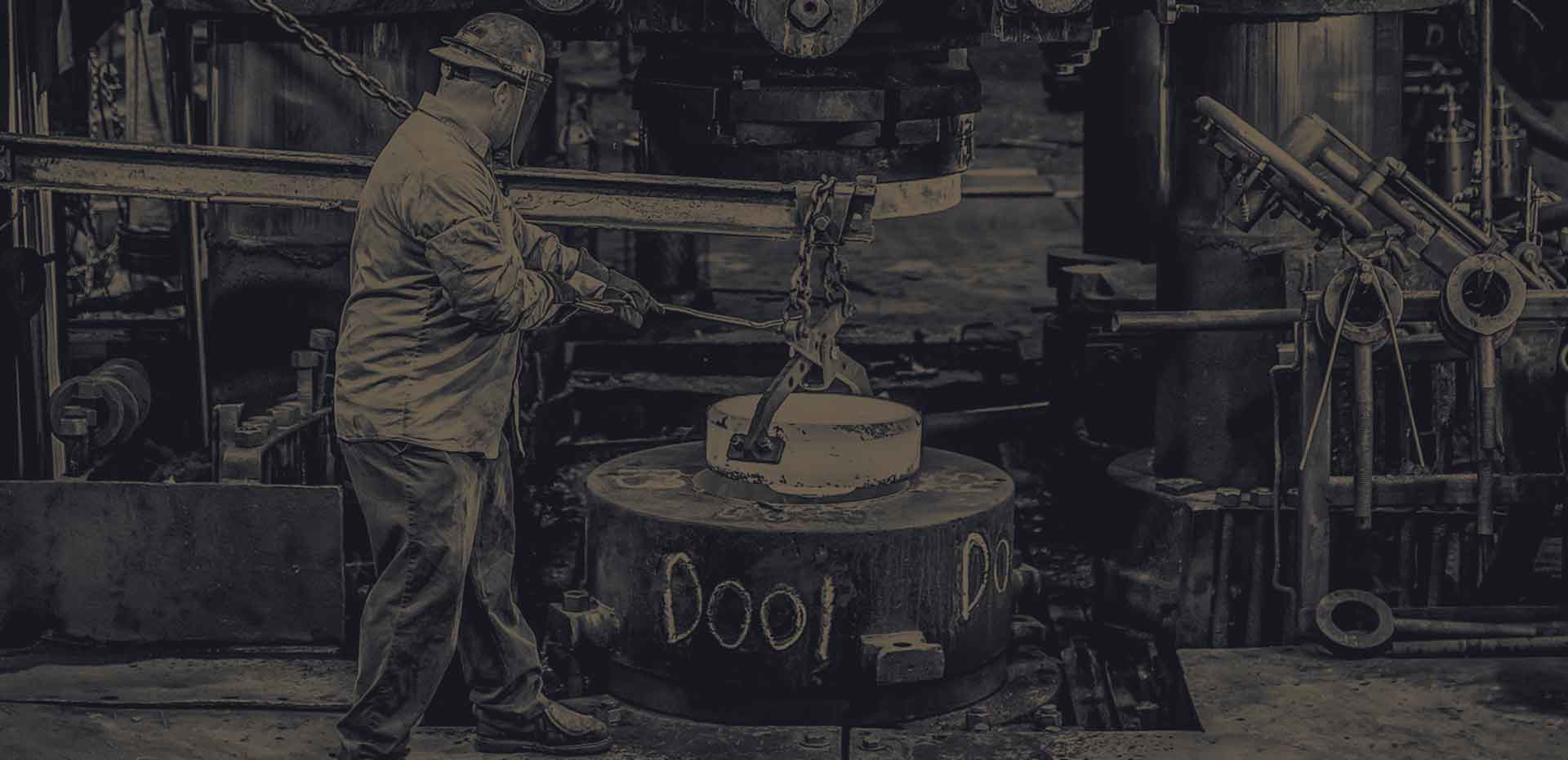

STRONG HISTORY AND A BRIGHT FUTURE

McConway and Torley has been a longstanding strong partner with companies and government agencies such as NAVSEA, AFRL, ARL and DOE in the Defense and Energy sectors. Our highly advanced metal making and processing combined with large sand molding and state of the art ingot making processes make M&T one of the most unique and flexible specialty metal producers in United States. DOE funded research to produce the largest Haynes 282 casting ever made. We continue to contribute to cutting edge research and development through the Steel Performance Initiative and Steel Founders Society of America. M&T Maintains NAVSEA HY80/100 ingot certification for forging ingots and we continue to expand our certification and development work through our Industry Partners.

TECHNOLOGY AT OUR CORE

…………………………………

…………………………………

M&T has a strong group of highly skilled and experienced technical leadership equipped with the latest Engineering and Inspection tools to support your casting and ingot needs. The Casting and Ingot Making processes at M&T utilize the latest melting, refining, pouring and finishing technologies including: Arc Furnace Melting, Ladle Furnace Refining, Vacuum Tank Degassing, along with the latest clean steel technology practices. We maintain a large compliment of MIL/AMS/SAE Certified heat treatment facilities and large component material handling equipment.

DROP US A LINE

…………………………………………… ……………………………………………