DESIGN & ENGINEERING

DESIGN & ENGINEERING

CAPABILITIES

…………………………………

…………………………………

Product Design & Engineering

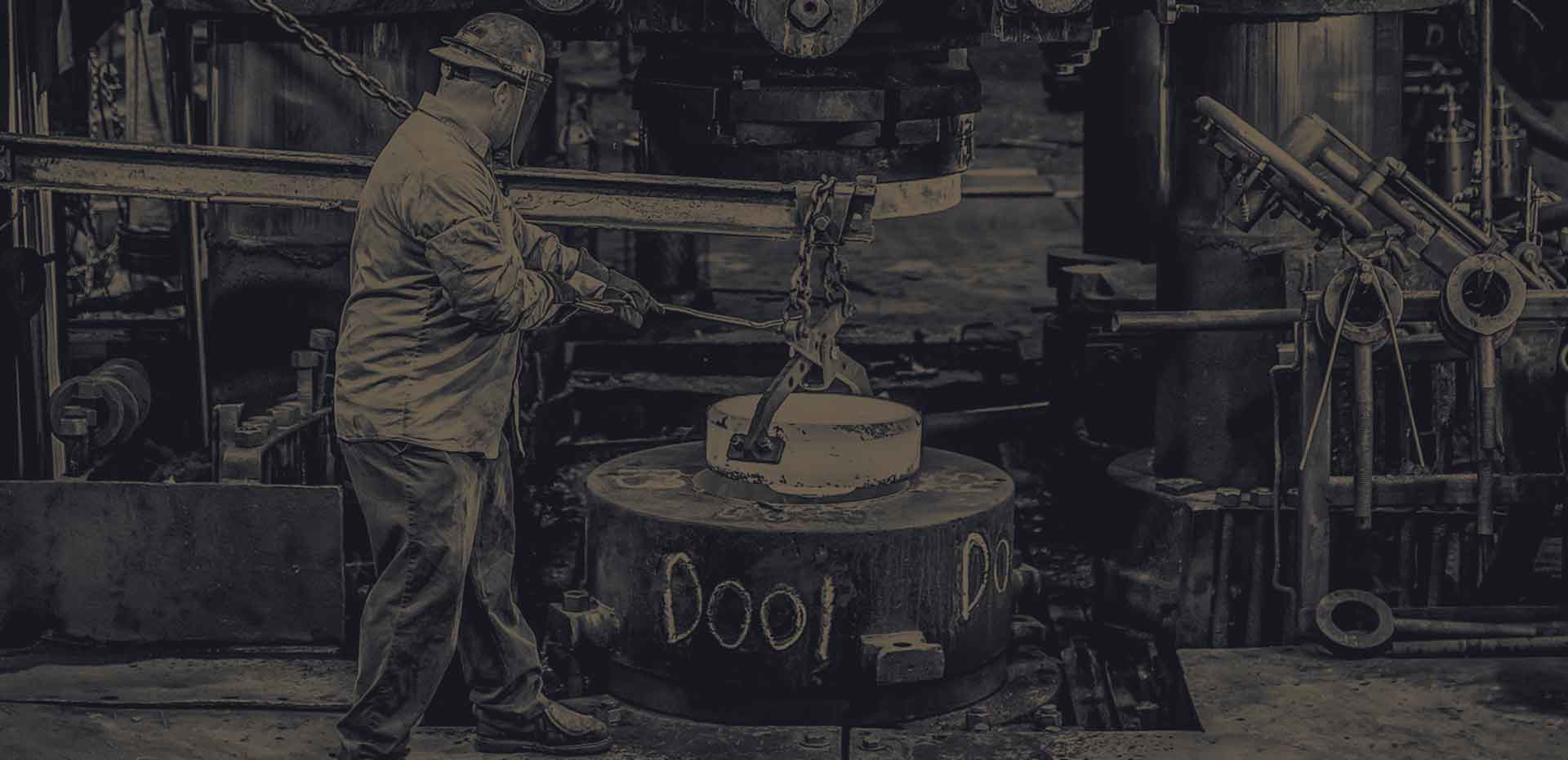

The ingenuity and expertise of McConway & Torley engineers is well documented. Historically our engineering innovations have resulted in new products, as well as product and process improvements. From reduced slack knuckles and couplers, to advanced mining components, McConway & Torley’s engineers have made significant product contributions to a number of industries.

The significant product innovations were made possible over the years by working closely with customers to provide solutions that satisfy their needs. Designing new products or developing improved enhancements to existing products reflects the interest of McConway & Torley to apply proven engineering expertise beyond its traditional product line.

This expertise is supported by the use of advanced engineering software such as:

- Creo Parametric, the CAD industry’s leading application for 3D product design. Using the right tool for the job can be enormously powerful for developing quality products that will exceed their specific requirements. Creo facilitates the creation of complex geometry necessary for accurate analysis throughout the engineering process.

- MAGMASOFT ® is the comprehensive and effective optimization tool for improving metalcasting quality, optimizing process conditions and reducing production costs. Consequently utilizing the methodology of virtual Design of Experiments and Autonomous Optimization, robust process parameters and optimized casting layouts can be established for all cast materials and processes including heat treatment and melt metallurgy – efficiently and comprehensively at the same time. A modular software design covers the complete process chain of cast components. The software can be applied for optimized process robustness and part quality from conceptual to final component design, during the tooling layout and prototyping, all the way through to the production and heat treatment processes.

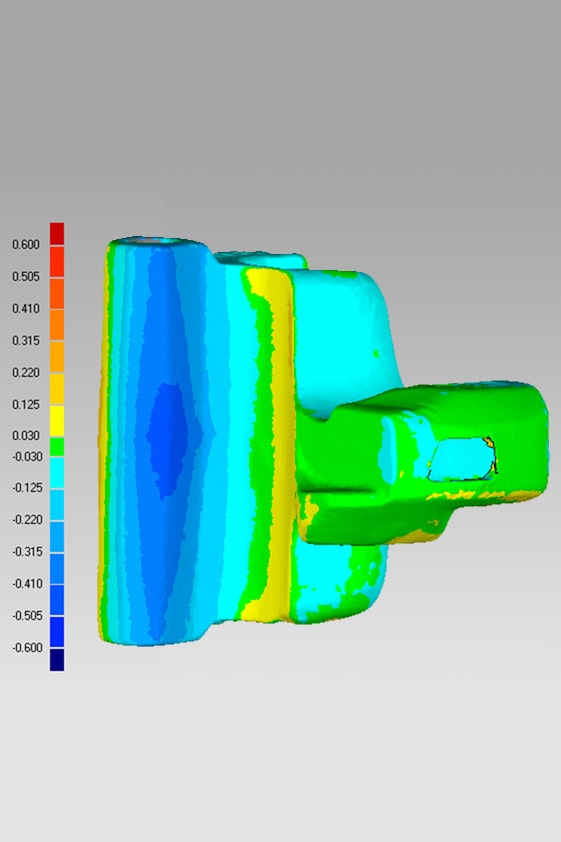

- ANSYS a structural analysis software which solves complex structural engineering problems and make better, faster design decisions. With the finite element analysis (FEA) tools available, M&T can customize and automate solutions for complex structural mechanics problems and parameterize them to analyze multiple design scenarios. The software connects easily to other physics analysis tools for even greater fidelity. Simulation of complex materials and material behavior can be achieved as well as models with very large deformation without simplifying geometry. The NonLinear ADaptivity (NLAD) capability automatically handles challenging simulations by remeshing the solution as it progresses. ANSYS structural analysis software is used throughout multiple industries to enable engineers to optimize their product designs and reduce the costs of physical testing.

It is with these tools and our expertise that M&T maintains our industry leading edge in product design and process innovation.

DROP US A LINE

…………………………………………… ……………………………………………

QUALITY RAIL PARTS AND EQUIPMENT

MARKET-LEADING EXPERTISE, PRODUCT, AND SUPPORT.